The collaborative project GreMeOH (Green H2 and MeOH in Denmark) funded by MissionGreenFuels is looking in to supply chains, integration, and manufacturing concepts with focus on speed and quality to pave the way for an increased capacity of installed plants producing green hydrogen and e-methanol.

By Julie Søgaard

As a part of the GreMeOH project, SDU researchers and the company Green Hydrogen Systems (GHS) have for more than a year been investigating how future manufacturing plants for PTX equipment can be constructed so they from the outset will be lean, digital, automated and flexible and ultimately competitive with respect to costs, quality and delivery performance in the global market place for electrolysis technology, which already today is very competitive.

Here, the first steps have been taken in developing a set of digital twin and material flow models for assembly of A- and X-series electrolyzers, which can support future digital design, operations, and maintenance of Denmark’s first large-scale manufacturing plant for Alkaline Electrolyzers located in the outskirts of Kolding.

“From our point of view as a company these are good tools to investigate what happens if we produce a certain amount in a year or what happens if we produce half of it. What strategy should we follow? How many shifts should we have? Where can we save money? Where can we optimize, and where is the bottleneck?”, Production Engineer at GHS, Shiva Gashtasebi, says.

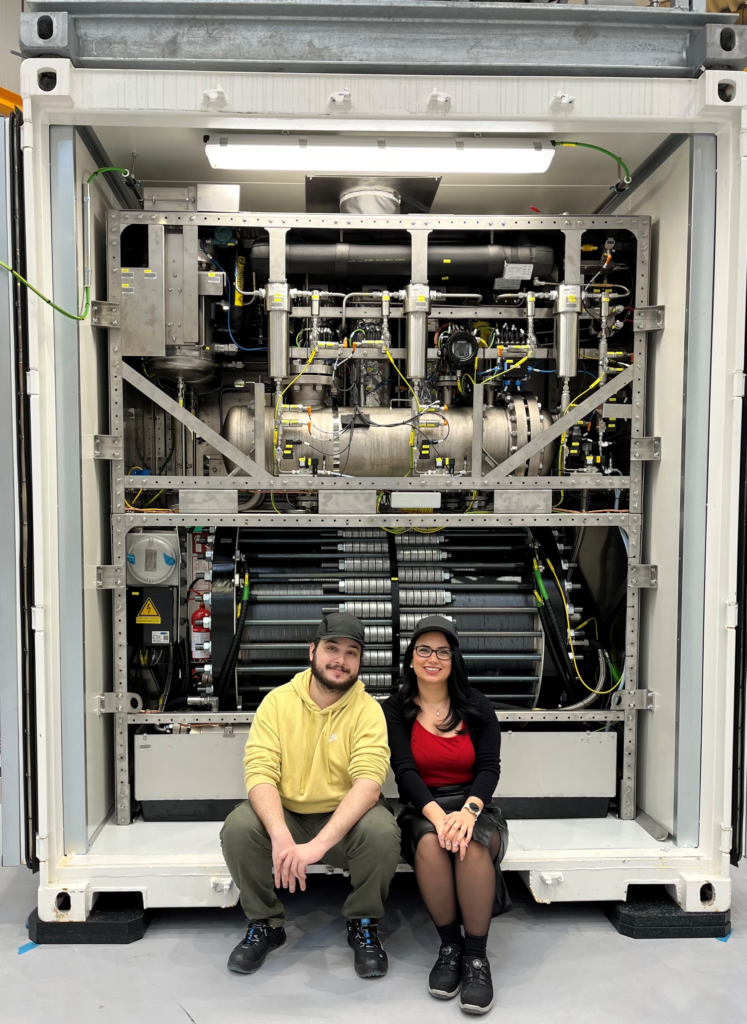

(The article continues below the picture).

Green Hydrogen Systems is one of Denmark’s vendors and frontrunners in the PTX industry offering a set of new innovative water pressurized electrolysis technologies expected to be of high quality and price-competitive compared to existing solutions in the European or global marketplace.

The last four-five months researcher Rui Goncalves from SDU has been visiting GHS weekly to get more familiarized with the operations and to develop the simulations models in close collaboration with Shiva Gashtasebi.

“Although our roles blend my focus is mostly to create the simulation and continuously improving the models we build,” Rui Goncalves from says.

“While I collect and feed him with data,” Shiva Gashtasebi adds.

Right now, they are working on upgrading the models and their data foundations.

“When it comes to building the model, we look at resources – both people, processes like QA inspections and machines. We also look at physical layout of a production and assembly times. And if a machine needs to be calibrated that’s also something we maybe can include at some level,” Rui Goncalves says.

So basically, everything that happens in the productions will be included, Shiva Gashtasebi points out.

In the end they expect to develop a discrete event simulation model that is as precise as necessary through cyclical modeling activities.

“We’ll have this experimentation environment where theoretically anything you want to experiment with production-wise, you’ll be able to toy around and tweak around in the model,” Rui Goncalves says.

So according to Rui Goncalves you don’t have to start from scratch if you want to have another production hall or facility later. You can just use the same software and edit it to fit the new facility.

Later in 2024 they are planning for test and validation of relevance for shop floor operations.